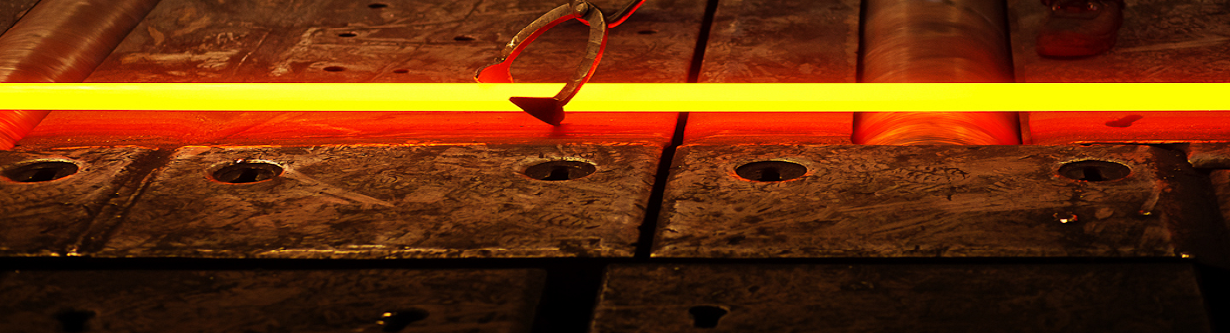

THIS PROGRAM INCLUDES THE BASIC FORGING EQUIPMENT AND ALL OTHER NECESSARY DEVICES FOR THE PRODUCTION OF VARIOUS FORGING PRODUCTS.

In our Forging program, we produce forged products:

forged billets, forged rods and forgings of different surface versions.

For smaller dimensions, we use the SX-40 forging machine, while larger ones are made on presses. We have 12 MN, 25 MN and 40 MN presses.

All these products can be subjected to heat treatment in modern heat treatment furnaces using different procedures.

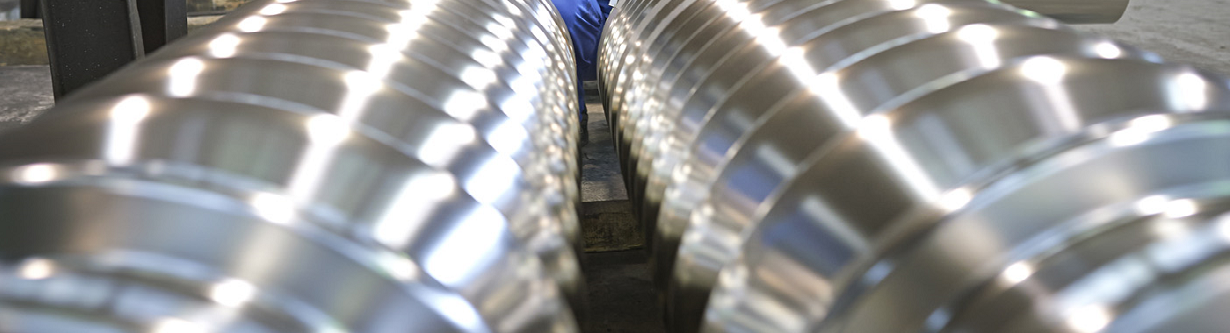

The important part of our Forging Program involves machines for machining and cutting of material.

In addition to products with unmachined surfaces, we can also make products with bright surfaces using the method of peeling, turning and milling. All these products can be cut into the required dimensions.

STANDARD DIMENSIONAL PRODUCTION & SALES PROGRAM:

Billets (product used for further hot forming)

Round: o 90-1000 mm, square: sq. 90-900 mm, length: 2000-10000 mm

Forged bars (acc.to DIN 7527/6 standard)

Round: Ø 90-1050 mm, square bars: 80-950 mm

Flat bars: from 90×60 mm to 1800×500 mm or 1200×700 mm or 1500×600 mm, length: 2000 – 10000 mm, max. diameter and weight: structural steel: Ø1050 mm, tool steel:Ø 950 mm,

special steel: Ø 800 mm

Forgings: max. dia.:Ø 1050 mm, max. length: 10 000 mm, max. weight of a forging: 27 000 kg, conventional: 29 500 kg, ESR: 24 000 kg, machined: 12 000 kg

Discs: max. external dia.: Ø 2500 mm, max. borehole dia.: o 1800 mm, max. weight: 28 000 kg

Bushes: max. external dia.: Ø 950 mm, max. borehole dia.: Ø 700 mm, min. external dia.: Ø 200 mm, max. length: 1900 mm

Machining: peeled: Ø 85 – 205 mm, turned: metal – 206-925, 10 m length, 10 ton weight,

Serpa – max. Ø 1150 mm, 6 m length, 30 ton weight, milled: max. width: 1200 mm, max. thickness: 1040 mm, length: 6 000 mm, weight: 10 000 kg. Forgings can also